Hobbyists and tinkerers are testing out the future with a technology that you're probably going to have sooner than you think.

The progression that computers made from IBM to your laptop has patterned the expectations for all future technologies. First, big companies create and use a very expensive set of technologies. Then, garage tinkerers start to use slightly cheaper, smaller versions of the original technology. They create a culture that makes the technology easier to use and they give it more users, which drives down its costs. Finally, when it is sufficiently cheap and easy to use, mass market consumers start to buy it. This is a condensed, reductive history of consumer electronics, but it's the mental model Silicon Valley-types have.

The latest technology that seems to be working its way along this trajectory is 3D printing. For those not in the MAKE crowd, 3D

Printers

are machines that produce three-dimensional objects from digital

data by printing in thin layers of physical material, similar to the

way an inkjet

prints in two dimensions. A 3D printer outputs not words on paper, but a thing. After a couple decades of research, development, and industrial deployment, the technology appears to be on the threshold of developing a mass market. Still, it's hard to imagine what to do with such a general purpose machine sitting in one's house.

And that's what makes Brendan Dawes such an interesting early adopter. For one, he's kept meticulous records of his productions since he bought his MakerBot Thing-O-Matic from Makerbot Industries, a company that sells stripped down

do-it-yourself 3D printers directly to consumers, in December 2010. Over the past year he has posted his "printings" on a tumblr called everythingimakewithmymakerbot. The site reads like a diary or sketchbook; an intimate account

of a creative person interacting with a new technology.

But more to the point: Dawes seems like a normal, creative person. He's not a hardcore geek with an industrial engineering degree. In the early nineties he

was a minor figure in Manchester's rave scene. He cut several 12"

singles, breakbeats

mostly, and even scored a record deal. More recently, he has turned his

attention to the graphic arts, and with considerable success: in 2009

several works of his were exhibited at the Museum of Modern Art in New York.

If a former-raver and artist could find fun and value in the $1,100 machine, maybe a lot of people might. And he did. "It took me a

week to assemble my Makerbot, but remember that when Jobs and Wozniak

and those guys

first started out, you had to make your own computer," he said.

"Now they're in your pocket. That's where I think this is headed." (Are you listening, Apple?)

The selection of things that Dawes printed in 2011.

Of course, in some ways, Dawes is ideally suited to fiddling around with a 3D printer. Last year he founded Beep Industries, a startup that manufactures an external shutter button for the iPhone. Before that, he worked as a commercial web designer, doing agency work for large media companies like Disney, Reuters, and the BBC. He knows his way around a computer.

Dawes is not alone in his obsession with the Makerbot. The machine has spawned a whole subculture of 3D printing enthusiasts. The website for Makerbot Industries features a forum called the Thingiverse, where customers can swap digital designs and post pictures of their latest creations. Because the early models of the Makerbot required a protracted and difficult home assembly, this first generation of users is an especially crafty group.

Shortly after Dawes purchased his Makerbot, he and his wife decided to remodel their kitchen. After the remodel, the couple discovered they'd misplaced

their egg cup in the chaos of packing and unpacking the kitchen. Dawes' wife, who had been slow to warm to his new hobby, was craving hard-boiled eggs.

He told her not to worry, he'd just print a new egg cup. And he did, in three minutes. The Makerbot forums are full of similar anecdotes,

making it easy to imagine a new model of online shopping, where consumers purchase and download digital designs from Amazon, iTunes, or wherever, and

print them right on the spot.

The three-minute egg cup.

Naturally, some are hesitant to hand such an efficient means of production to the masses. Manufacturers (and intellectual property lawyers) have taken note of the way the music and media industries have struggled with the accelerating transmission and duplication of content. When it becomes feasible for a consumer to print a complex structure like a grandfather clock or an iPhone, the stakes of preventing the dissemination of ideas are raised considerably. Already at Pirate Bay, the torrent site the L.A. Times called "one of the world's largest facilitators of illegal downloading," a new category of downloads has surfaced: objects.

Future entrepreneurs will have to decide whether the proprietary risks of at-home 3D Printing are worth the benefits. More likely, the market will

decide for them. One upside of at-home printing is that it allows for product customization on an unprecedented scale.

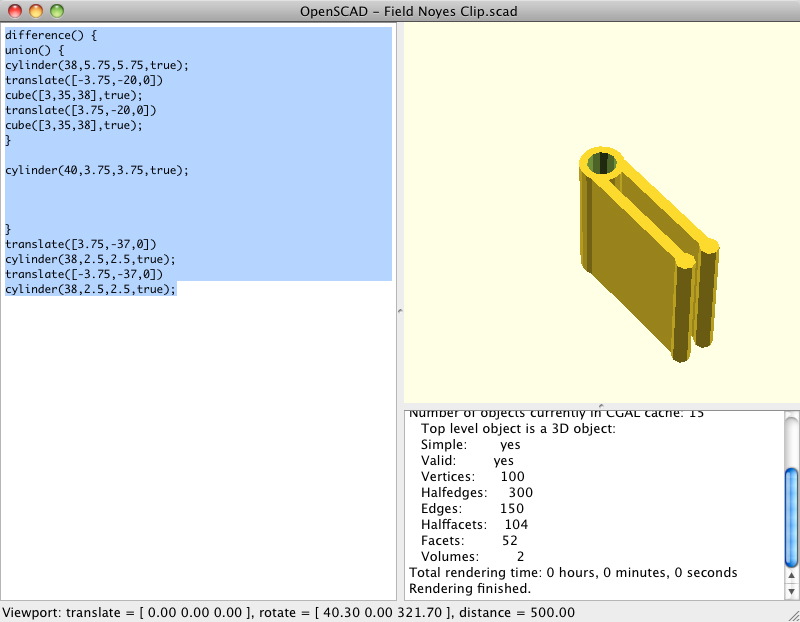

The 3D model for the field notes pencil clip.

In November, Dawes was browsing

the Makerbot forums when he came across a picture of a pen clip for a Field Notes Memo Book, his

favorite notebook. There was only one problem: Dawes prefers pencils, which are slightly thicker than the pens the clip was designed for. No matter; he

was able to download the design, tweak it to fit a pencil, and even add a cap to prevent pencil lead from staining his clothes. It is this feature,

this layering of innovation upon innovation that thrills Dawes about the future of 3D printing. "It's exciting to download physical products, to remove

the supply chain and all of that," he said. "But what's more exciting is the ability to buy a product online and then add your own dimensions to

it in a very simple way."

The Field Notes pencil clip in action.

In recent years, cultural critics have bemoaned the way technology has removed us from the physical details of things, from knowing how machines work. The idea is that by retreating from manual work, from mastering physical tools, we're marginalizing ourselves and diminishing some of our most essential capacities. Matthew Crawford has been especially articulate on this front. In his provocative book Shop Class As Soulcraft, he writes:

"The disappearance of tools from our common education is the first step toward a wider ignorance of the world of artifacts we inhabit. And, in fact, an engineering culture has developed in recent years in which the object is to 'hide the works,' rendering many of the devices we depend n every day unintelligible to direct inspection. Lift the hood on some cars now . . . and the engine appears a bit like the shimmering, featureless obelisk that so enthralled the proto-humans in the opening scene of 2001: A Space Odyssey. Essentially, there is another hood under the hood. "

3D Printing is unlikely to prove as satisfying to manual labor evangelists as an afternoon spent with a monkey wrench. But by bringing more and more people into the innovation process, 3D printers could usher in a new generation of builders and designers and tinkerers, just as Legos and erector sets turned previous generations into amateur engineers and architects.

Another colorful 3D-printed creation.

When researchers at M.I.T. patented a new technology called "3-Dimensional Printing" they probably did not imagine husbands printing egg cups for their skeptical wives. The technique was derived from a machine called the stereolithograph which was first developed by Charles Hull in the early 1980s. Today, 3D Printers are used to make everything from violins to titanium aircraft parts, and some think that one day they may even make skyscrapers. Large manufacturers are especially keen to the transformative potential of 3D printing, and they've invested accordingly.

In 1993, around the time the M.I.T. engineers were working out the printing process, the molecular engineer John Storrs Hall coined the term "utility fog" to describe a new theoretical concept in nanotechnology. A utility fog, as Hall conceived it, would be a swarm of nanobots capable of assembling into different physical structures. The tiny robots (foglets) would have retractable arms that, when connected, would allow for the transfer of energy and information.

Hall initially envisioned the microscopic shape-shifters coalescing into everyday forms like seatbelts, but futurists soon imagined something more elegant for the union of mind and machine. In addition to assuming forms of great complexity, the utility fogs of science fiction could become invisible, and even teleport. Transhumanists wondered if utility fogs might one day replace humans as the ideal physical embodiment of consciousness. And no wonder. The utility fog concept captures the basic id of technology: the impulse to reorder the invisible fabric of the universe into some spectacular new form, and to summon that form to the surface of experience.

The tech press could not help but combine Hall's idea with the new machines that printed objects. They were agog at the possibilities suggested by the new technology. Here at last was a primitive utility fog: a machine that could make machines. And now, for the price of a very crappy used car anyone can have a machine that can make machines.

I asked Dawes if the Makerbot had changed him; if it had altered his perspective in some unexpected way. "What's exciting to me is the opportunity to look at industrial design --a very difficult, very sophisticated craft-- with fresh eyes. I'm able to approach these problems from crazy angles, because I haven't spent twenty years immersed in the culture of industrial design," he said.

"That and it's sort of magical to have this thing sitting at home, this thing that makes physical objects out of nothing," he said. "It's just amazing."

If Steve Jobs was right that the computer is a bicycle for the mind, the 3D printer may just be its factory.

Images: Brendan Dawes.

We want to hear what you think about this article. Submit a letter to the editor or write to letters@theatlantic.com.